Steps to follow for weighing a truck with airbag suspension with onboard vehicle scales.

Weighing a truck with airbag suspension involves several steps to ensure accurate measurements. Here’s a general guide on how to weigh a truck with airbag suspension:

- Find a Suitable Weighing Location: Look for a certified weigh station, truck scale, or commercial facility equipped to weigh trucks. Ensure that the location has a scale with a sufficient weight capacity to handle the truck’s load.

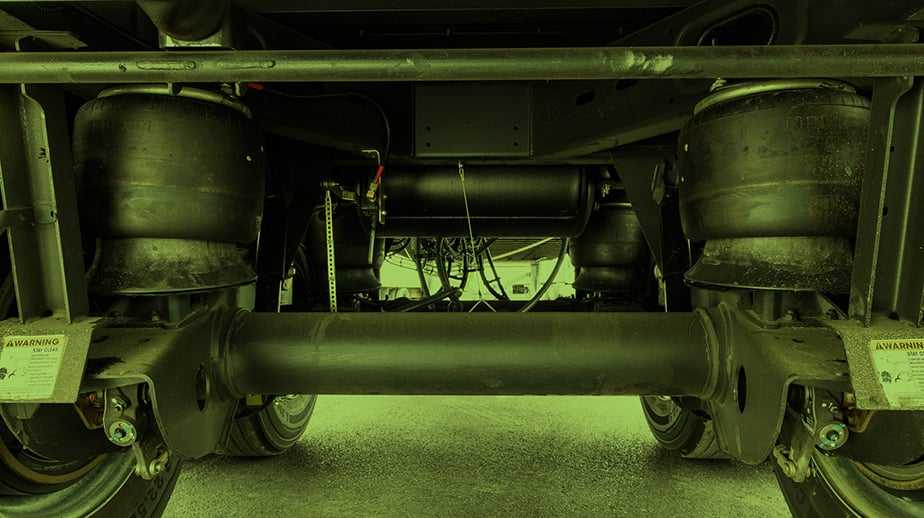

- Prepare the Truck: Park the truck on a level surface. Engage the parking brake and turn off the engine. If applicable, adjust the airbag suspension to the appropriate ride height or level position according to the manufacturer’s instructions.

- Determine Axle

Configuration: Identify the truck’s axle configuration, including the number of axles and their locations (front, rear, trailer). This information is crucial for calculating weight distribution across the axles.

Configuration: Identify the truck’s axle configuration, including the number of axles and their locations (front, rear, trailer). This information is crucial for calculating weight distribution across the axles.- If weighing on a vehicle Weighbridge, drive onto the Scale: Slowly drive the truck onto the scale, positioning each axle or set of axles on separate sections of the scale. Ensure that all wheels are on the scale platform and not hanging off the edges. Follow any specific instructions provided by the weighing facility.

- Distribute the Load: For accurate weight measurements, distribute the load evenly across the axles. Ensure that the cargo is centered and secured properly. Uneven load distribution can affect the accuracy of the weighing results.

- Obtain Weight Measurements: Once the truck is positioned on the scale and the load is evenly distributed, obtain the weight measurements for each axle or set of axles. Depending on the scale, these measurements may be displayed digitally or provided on a printed ticket. Make note of the weights for future reference.

- Calculate Total Weight and Weight Distribution: Use the individual axle weights to calculate the total weight of the truck. Add up the weights of all the axles to obtain the gross vehicle weight (GVW). Analyze the weight distribution to ensure it complies with legal requirements and manufacturer recommendations.

- Adjust Airbag Suspension if Necessary: If the weight distribution is uneven or outside the desired range, make adjustments to the airbag suspension system according to the manufacturer’s guidelines. This may involve inflating or deflating specific airbags to achieve the desired weight distribution.

- Repeat the Process if Needed: If necessary, repeat the weighing process to ensure accuracy or if there have been significant changes to the load or weight distribution.

- Document and Record the Results: Record the weight measurements, weight distribution, and any necessary adjustments made to the airbag suspension system. Keep this information for reference, compliance purposes, and future load planning.

It’s important to note that the specific steps may vary depending on the type of scale, facility requirements, and the truck’s airbag suspension system. Always refer to the manufacturer’s instructions and follow any guidelines provided by the weighing facility for accurate and reliable results.